Factory Automation

Overcoming Labor Constraints with Factory Automation

The pandemic has fundamentally changed the manufacturing industry. Supply chains around the world have become long, complex, fragmented and unreliable.

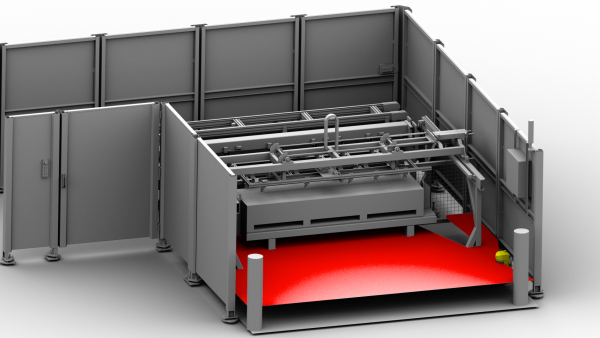

At Facteon, we design safety into factory automation systems from the outset, ensuring that operating processes are simpler and safer for human workers, while making automated lines more productive.

Automation solutions, from robots through to conveyor belts can make the workplace safer by taking the dirty, dull and dangerous jobs away from humans. They can however, also add new hazards if they’re not designed, manufactured, programmed, or maintained correctly.

While it’s one thing to build guarding around automated machinery to keep people away, there are times when human interaction is needed—to reload, reset, or reprogram the unit, for instance.

“Safety must be embedded from the very earliest stages of design,” says Lawrence Owen, Senior Mechanical Design Engineer at Facteon. “At its heart, safety design is the science of striving to ensure nothing ‘interesting’ happens on a production line.”

The hierarchy of controls sets out the accepted order in which to apply safety solutions. The first two tiers are elimination (physically removing the hazard) and substitution (replacing the hazard). Next come engineering controls and administrative controls, followed by giving workers personal protective equipment (PPE).

“This isn’t to suggest workers don’t need PPE,” notes Lawrence, “but rather that boots and gloves are no substitute for designing hazards out of automation in the first place.” And that’s how we approach it at Facteon: safety is baked into the process right from the start.

There’s a popular saying: If it’s too difficult, you’re probably doing it wrong. Certainly, when working with automation, the path of least resistance is the best and safest way of operating.

“We deal with real-world scenarios,” explains Lawrence, who is a Certified Machinery Safety Expert. “There’s no point designing safety on paper if it’s likely that operators will break the rules to do their job and so endanger themselves. We must ensure that the quickest and easiest way is also the safest way.”

“Generally, we like to avert situations where operators have to interact with heavy machinery,” explains Lawrence. “But if they have to interact, and that takes us up to performance level ‘e’ [an ISO designation for the highest risk level ], then our job is to ensure the most stringent safety standards are met.”

So we’ll typically take a concept design through multiple iterations until we and the client are all satisfied with the solution and it’s signed off. It ensures we have the best chance of catching any safety issues before the design enters production. Modelling the whole line—showing new machinery in relation to any existing plant—is key too. “The final step,” adds Lawrence, “is to ensure that the commissioned machinery matches our digital expectations, because the real world can hold a surprise or two.”

Whilst our core business is installing complete automation lines, we will also integrate new solutions into existing processes. In these scenarios, we’ll spend time on-site, closely inspecting the client’s equipment in order to perfect the fit. On every project, our risk assessment documents remain live from concept to sign-off to ensure we’ve foreseen hazards and completed all physical checks. And after sign-off, that documentation is stored in the company archive.

Safer practice leads to happier workers, and vice versa. “By automating low-end tasks, and integrating better processes into them, staff avoid downtime from repetitive strain injuries, or dissatisfaction arising through boredom from repetitive work,” says Lawrence. “If there’s an unpleasant job, we can automate that—take the worker out of it. They can then be moved into a role that’s more fulfilling, interesting, and useful, which helps improve staff retention. So it might all begin with safety in mind, but the benefits go far beyond safety alone.”

Safety measures that are embedded into processes, and backed up by full compliance with legislation, help protect anyone who steps into those roles, while also boosting productivity. It’s about making automated lines safer and more enjoyable for workers and managers with a focus on simplicity and mitigating risk from the start.

Speak with one of our team to find out whether your business will benefit from smart manufacturing solutions. Contact Facteon here via our contact page.