From automated laser welding to robotic MIG welding, we take you through a range of welding technology used in smart factories today.

Fully automated welding suits long, consistent production runs of repeatable processes. An automated line can work for extended periods without breaks and cover multiple shifts with no time limits. Automating welding processes also addresses safety issues in advanced manufacturing and assembly lines by preventing human exposure to heavy lifting, fumes and heat.

When it comes to product design and quality, automated welding offers significant advantages in product performance and appearance. We start by assessing the physical characteristics of products – such as materials and gauges, size and geometry, strength and appearance – to define the best processes and technologies.

While product design certainly drives solutions, products might also need to be designed in specific ways to facilitate welding. We use a co-creation approach to maximise customer–engineer collaboration and identify the optimal outcome. In addition, product quality, budgets, delivery time and production targets are all factored in.

We draw on a range of trusted and best-in-class welding suppliers when assessing welding equipment for a project. Where our customers have a preferred supplier, we will integrate their equipment into the line to simplify factory maintenance.

In addition to our deep specialisation in laser-welding stainless steel, we employ a range of welding technologies to suit the physical characteristics of the products. Below are some of the considerations we guide our customers through during the concept design phase to optimise automated manufacturing and assembly lines.

Laser welding

Laser welds are very clean and visually appealing. Although they might be relatively costly to set up, it’s relatively inexpensive to run. They generally operate in dedicated cells (within an enclosure for safety), which stand alone or are integrated into a production line. They’re often used for high-volume runs where the finished product is visible to consumers (such as washing machine drums), and widely used in making automotive panels and medical equipment.

Spot welding

Spot welding is one of the cleanest of the welding types. The welding electrode produces only a few sparks and little smoke (mainly when there’s oil residue on the sheet). Spot welding is often used in the automotive industry, furniture and appliance manufacturing.

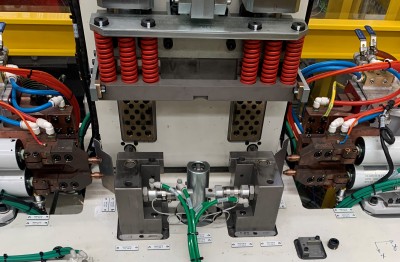

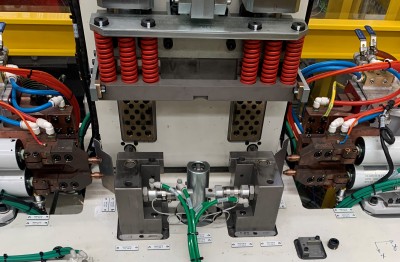

Fixed automated spot-welding cells are suited to components that require several welds, and allow for a few model variations, product dependent. Depending on the process, it may also be possible to perform another function within the cell, such as folding, followed by welding.

Robotic spot welding offers more flexibility and can handle wider product variation, as well as perform more welds per product. For example, a single gun can perform 20-plus spot welds, and multiple robots can perform spot welds simultaneously within a machine or down a production line.

With robotic cells, we can also offer auto tip dressing or auto tip changes to minimise manual tip changeovers on spot welders. The automotive industry has long favoured robotic spot welding.

Resistance welding

Resistance seam welding is similar to spot welding, except that circular rotating electrodes are used, which can create an air- or fluid-tight seal. It’s used to make steel fuel tanks for motor vehicles, and also for applications making tin cans, steel drums and domestic radiators.

The process lends itself to welding seams that are straight or have a regular curve. Abrupt changes in the weld line in any direction should be avoided, and because of access issues it can’t weld into internal corners or other tight places.

Plasma welding

Plasma welding is done at extremely high temperature and requires precision alignment, making it an ideal process for automated welding. Temperatures of nearly 16,000 °C are applied precisely to very small areas, producing very clean and tidy, high-quality welds. It’s often used in manufacturing small metal components, steel tubes like exhaust pipes, and medical devices.

Given the unique advantages and restrictions of each welding method, we carefully tailor solutions to meet product design requirements. When there are alternatives to consider, we’ll present the best options to our customers, discuss the pros and cons, and then support them in choosing the right system.

Robotic MIG

MIG technology can weld together heavier-gauge materials and perform different kinds of

welds, such as lap welds, fillet welds and butt welds (unlike spot welds, for instance, which are limited to lap welds). Robotic MIG is a good option where higher strength is required and there are multiple weld types on a single product.

MIG welding can use standard industrial robots or cobots. Generally, industrial robots are used for more complex products and processes, where we can also offer automated gun cleaning solutions. For small runs of small to medium-sized products, it’s easy to teach a cobot a function by simply moving the MIG gun to demonstrate where the welds go.

Introducing automation and/or robotics into a business is an investment that can revolutionise the manufacturing process. Facteon provide you with access to the right technology, advice and experience to implement a robust and profitable automated welding solution.

Find out more

Speak with one of our team to find out whether your business will benefit from robotic or automated welding technology. Contact Facteon via our contact page.