Custom Machining

Custom Machining in the Internet Age

Facteon takes pride in offering innovative and high accuracy machining capabilities. We have a dedicated, in-house Machine Shop.

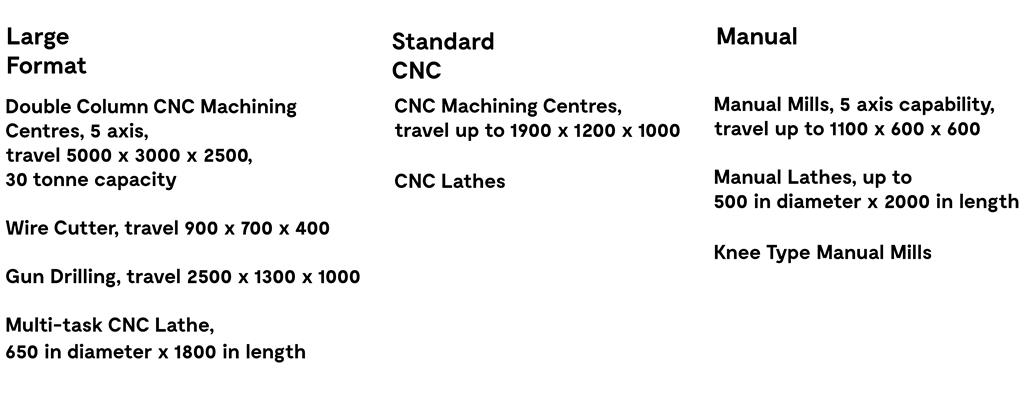

Many of Facteon’s Machine Shop projects are critical to our clients' successes. So, we’re sworn to secrecy via non-disclosure agreements. However, there are a few projects we can share with you. Our CNC machines, manual mills and large format machines have been working overtime.

- Machining spare parts for production lines

- Small batch runs

- Large scale machining of fabrications

- Producing one-off, quality prototype parts.

Here at Facteon, we like to keep busy, we’ve had close to four decades to practice. We balance internal machining work for Facteon’s Build Shop with a range of jobbing work for our fellow innovators.

We keep good company in doing work for multinationals through to local, New Zealand-based engineering shops. We never know what is going to walk through the door. We’ve recently completed projects for medical, construction, heat exchange, compressor and metallurgy industries. We even support other machine manufacturers.

To deliver for our customers, we employ world-class machining techniques. This ensures every customer receives an expertly machined part that meets their quality standards. Facteon’s manual milling machines are capable of five-axis milling and provide the flexibility of over a metre of travel. We often utilise this machine when a customer requires one-off, multi-featured components. We believe the key to producing fit-for-purpose components is combining traditional machining techniques with the latest technology. No matter how advanced machines become, they can’t achieve much without a skilled operator. For this reason, we’re committed to continuously providing training and fostering an environment in which learning is encouraged. We do this through offering both internal and external training programs to keep our tradespeople at the top of their game.

At Facteon, we love what we do. The Machine Shop team consists of 15 tradespeople. Collectively, the team holds over 400 years of experience on the tools. We’re passionate about shaping a piece of metal into whatever you need to make your operations tick. Most importantly, we always deliver on-time and to specification. Operating two shifts per day, six days a week, there are plenty of hours in the day (and night) to get the job done.

Let’s get down to the details: