To celebrate International Women’s Day 2025, we sat down with Dr Yan Jia, Facteon’s Concept Engineering Team Leader, to learn more about her journey, the challenges she has faced, and her vision for the future of women in engineering.

- « Previous

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- Next »

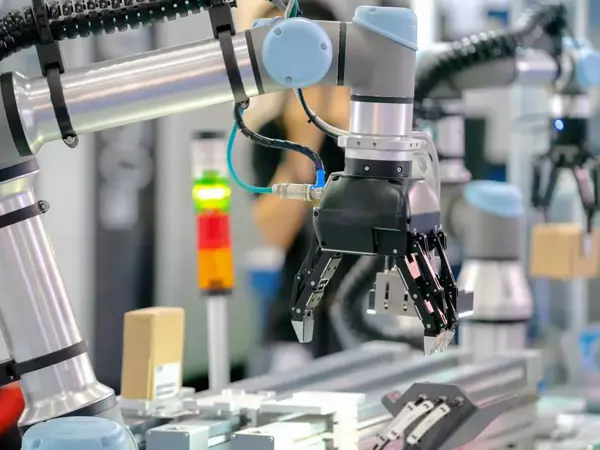

As the manufacturing sector continues to evolve, automation has emerged as a key driver of efficiency, scalability, and innovation.

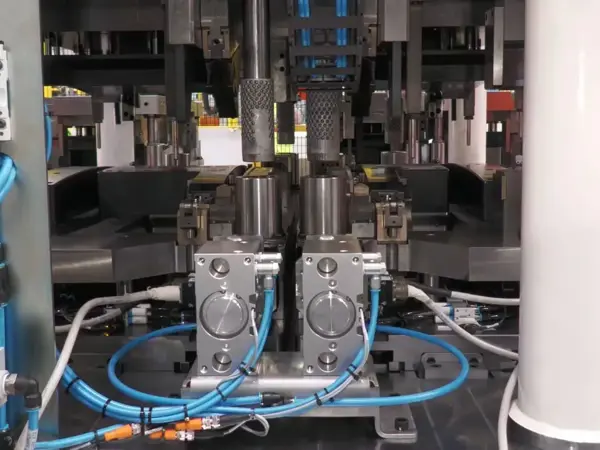

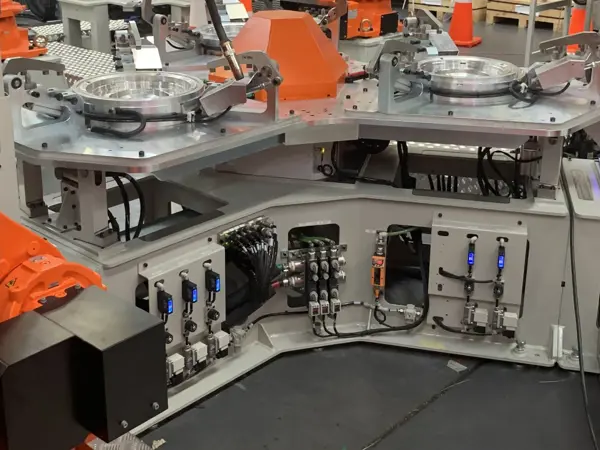

Our latest tool change technology enables our customers to dramatically reduce the amount of downtime, operational costs and health & safety risks during product model changeover events, while maximizing floor space utilization.

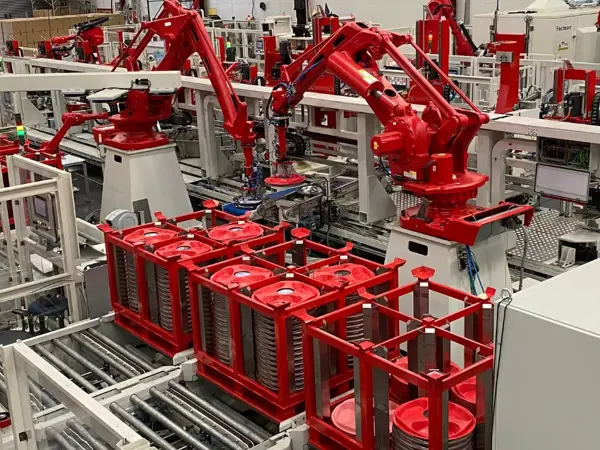

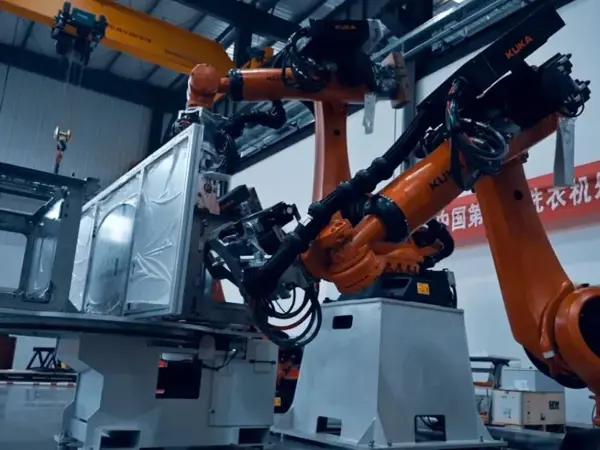

New robotic pallet destacker co-designed with CHEP uses ultrasonic smarts.

At Facteon, compliance to high standards underpins our co-creative design process, ensuring a safe workplace at no cost to your productivity.

here are growing career opportunities for women in engineering, where their mindset and skills contribute to a dynamic industry at the forefront of technological change.

Now that manufacturing is “coming home,” and adopting smart manufacturing, it’s time to build a skilled labor pipeline that will nurture the future factory workforce.

In the global push to adopt smart manufacturing, certain factories, known as “lighthouses,” are streets ahead, setting new benchmarks—and leading the way.

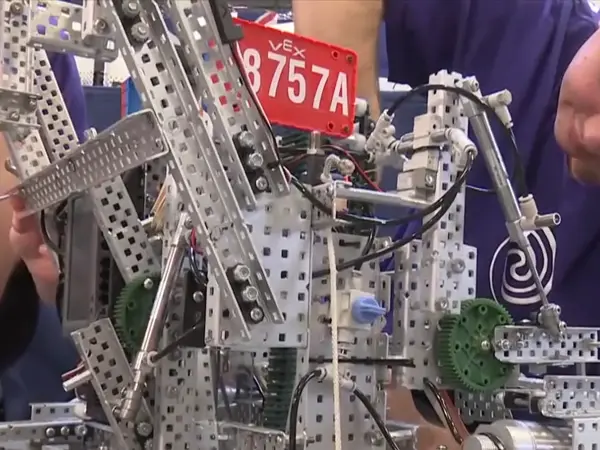

Facteon is proud to once again sponsor the New Zealand STEAM-ED Robotics team to compete in the 2023 VEX Robotics World Championship in Dallas, Texas.

To recognize International Women’s Day 2023, we spoke with some of our female employees to find out more about diversity in the industry and how we can attract more women.

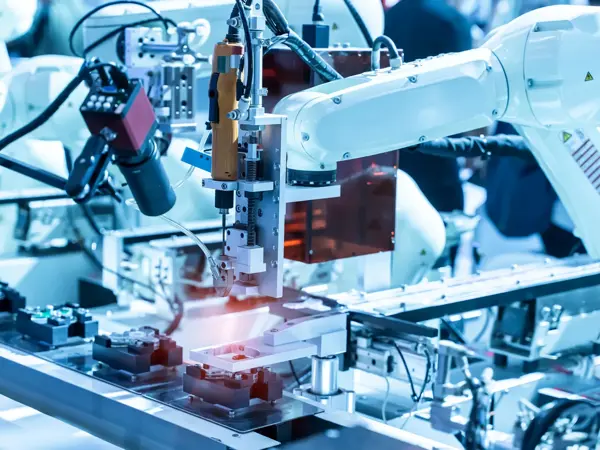

Automation isn’t just for complete production lines anymore. We’re now getting more involved in single cell or single operation solutions and problem solving where it could be 2-3 cells or even single cells delivered.

Find out how automation can reduce your scrap rate, and raise your profit margin and company profile, by fine-tuning your efficiency and quality control.

Facteon is delighted to participate in the 19th International Conference on Automation Science and Engineering (CASE).

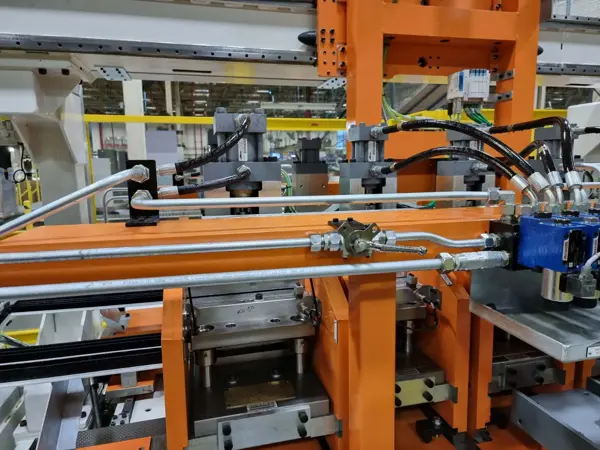

To conclude our series comparing hydraulic, pneumatic, and electric actuators, we explore how electric actuators are the technology of choice when accessing the Industrial Internet of Things (IIoT).

It’s never been a better time to grow and transform advanced manufacturing in New Zealand.

Both pneumatic and electric actuator systems are worthy successors to hydraulics—so long as you know their strengths, limitations, and ideal applications.

A computerized maintenance management system (CMMS) is the “brain” that takes the strain out of running maintenance in a manufacturing business.

In the first of a three-part series, we take an overview of what smart, data-driven manufacturing can do for productivity and profitability.

Meet Mark, our newly appointed Regional Director for North America. Mark will be working with the Senior Leadership team to launch Facteon’s presence in North America.

In a new three-part series, we will guide you through the process of moving on from hydraulics to new power systems. Hydraulic systems in one form or another have powered factories for centuries.

Facteon have spent the past four decades crafting factory automation and proprietary welding solutions and have grown to become international specialists in factory solutions, smart manufacturing and IIoT technologies.

Meet Kate, our recently appointed HR Manager. Kate oversees Facteon’s HR function at an operational and strategic level.

Risk mitigation is vital to every project. At Facteon, we manage and mitigate risk at every step, from supply chain issues to safety and technical performance.

At Facteon, we design safety into factory automation systems from the outset, ensuring that operating processes are simpler and safer for human workers, while making automated lines more productive.

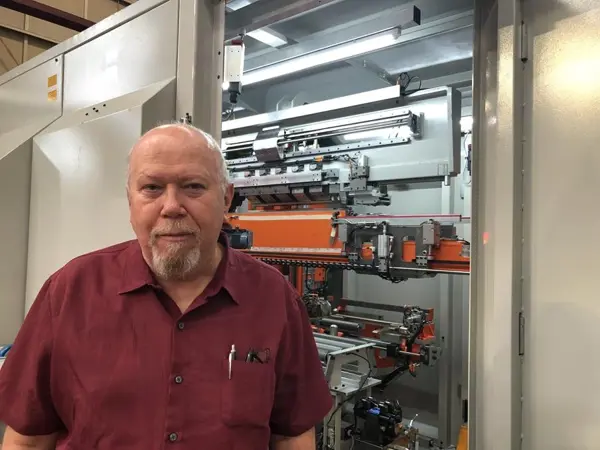

Warren Collenette tracks his 37-year career at Facteon. Warren Collenette has always loved making things run better, work faster and flow more efficiently.

Robots could revolutionize your business - the trick lies in knowing when, where and whether to use them.

When it comes to upgrading or enhancing an existing manufacturing and assembly line, an agile solution allows a manufacturer to address challenges in their process or changes in the market.

Mark your calendars for EMEX 2022 - NZ’s largest technology show for the engineering, manufacturing and electronics industries.

With the current environment of supply chain uncertainty and price inflation, we’re seeing huge interest in reshoring where businesses bringing all or some aspect of their manufacturing back home.

Facteon is delighted sponsor the New Zealand STEAM-ED Robotics team to compete in the 2022 VEX Robotics World Championship hosted in Dallas, Texas.

The pandemic has fundamentally changed the manufacturing industry. Supply chains around the world have become long, complex, fragmented and unreliable.

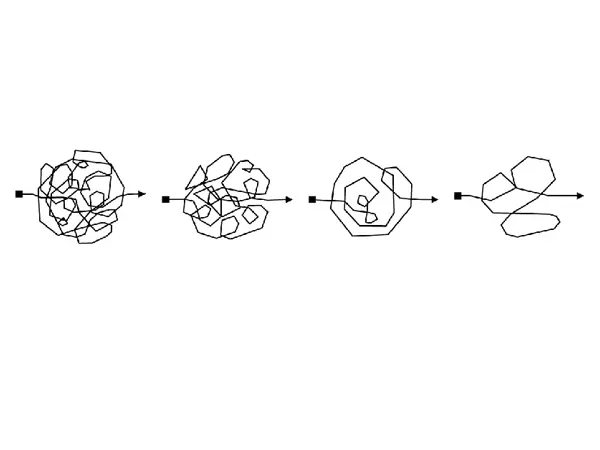

Robot simulation is used during the early analysis and planning phases of advanced manufacturing to save time and minimize the risks associated with robotic automation.

We take you through a range of welding technology used in smart factories today. In co-creation with our customers, we employ a range of welding technologies to suit the physical characteristics of the products.

Creating innovative, flexible, industry leading solutions along with the highest quality customer experience is our priority this year.

Random bin picking plays a pivotal role in advanced manufacturing environments and is suitable for applications that have tight cycle times and require accurate placement of parts from large storage containers.

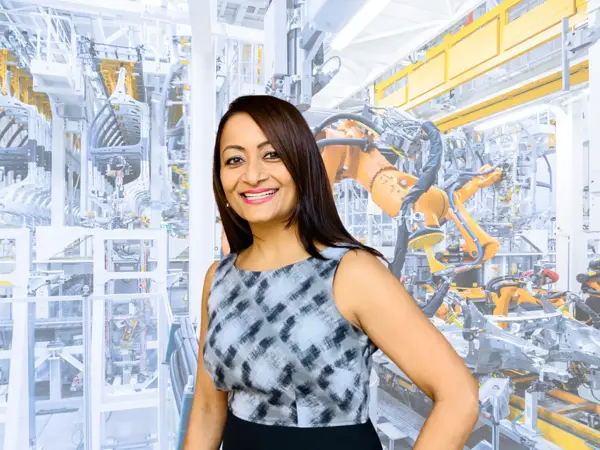

Meet Anjna Lal, our Marketing & Communications Manager. In alignment with Facteon’s vision, Anjna seeks to communicate our value proposition and elevate our thought leadership as an expert in factory automation robotics.

Before signing that purchase order to implement your new Industrial IoT (IIoT) solution, ask the right questions.

Group GM, John reflects on 2021 as a year of continued resilience, expansion and growth.

We look at machine vision: what it is, how it functions in the future-facing industrial environment, and whether it’s right for your business.

As with any new technology implementation, there can be a discrepancy between expectations and reality.

There could be no more suitable location than Chicago, in the industrial heartland of the Midwest, for the long-awaited return of FABTECH after a two-year hiatus.

The technology we have developed simplifies the process of teaching a robot a user frame.

The Manufacturers’ Network’s Dieter Adam sits down with Facteon to discuss the state of play in the manufacturing industry.

Microsoft’s HoloLens is a break-through mixed reality technology.

I’m enjoying the opportunity to contribute to the whole process", says Mathias speaking of his role with Facteon.

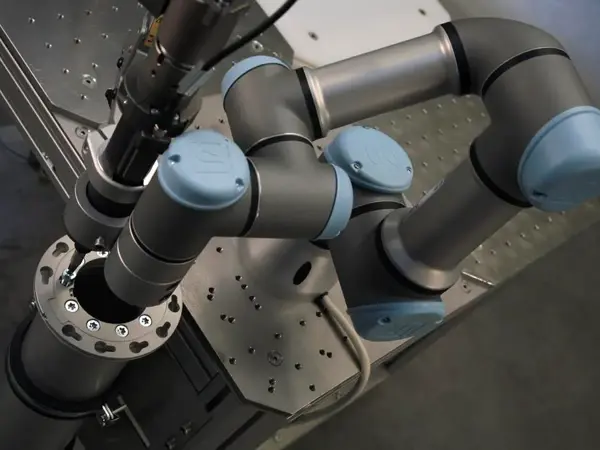

Guillermo reflects on the potential of cobots in the manufacturing industry.

Joining Facteon for the Summer of 2020/2021, Debbie swapped textbooks for robot simulations and sleep ins for daily team stand ups.

Persequor, iTrazo and Facteon bring end-to-end traceability to the fresh food space.

After a year of social distancing, a sense of normality was experienced in returning to a tradeshow in Auckland, New Zealand.

Facteon announces its partnership with one of New Zealand's leading industrial automation and electrical service providers, Dalton Electrical.

Facteon recently made the decision to bring our IT support function in-house. Meet Brendon, our IT Specialist.

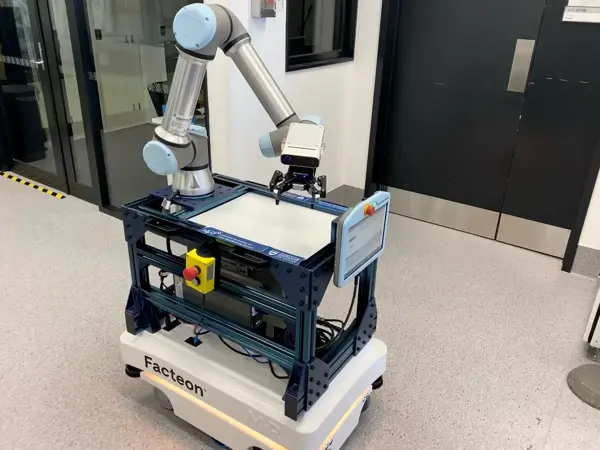

The University of Auckland’s Smart Manufacturing Lab created a flexible, autonomous robot with applications across goods transportation, loading and unloading of parts and co-manipulation of manual work.

This piece serves as your reintroduction to the laser technologies set to shape manufacturing in 2021.

Earlier this month, the Facteon team geared up to co-exhibit alongside our partner, Kemppi at EMEX 2021.

Weiming and Joseph are the latest additions to our growing Digital Manufacturing and Automation team.

Whether your manufacturing business thrived or survived 2020, it was a year of unpredictability, adaptability and new technology for many.

Hailing from the fast-paced and technology-powered IT industry, Rob shares his thoughts on manufacturing in 2021.

Working alongside the best. Debbie and Vincent have kick started their engineering careers with the experts.

Group GM, John, reflects on the year that has been and shares his vision for a remarkable 2021.

Peter Beck, CEO of Rocket Lab, introduces Rosie the Robot. Or as we call her, Facteon’s latest innovation.

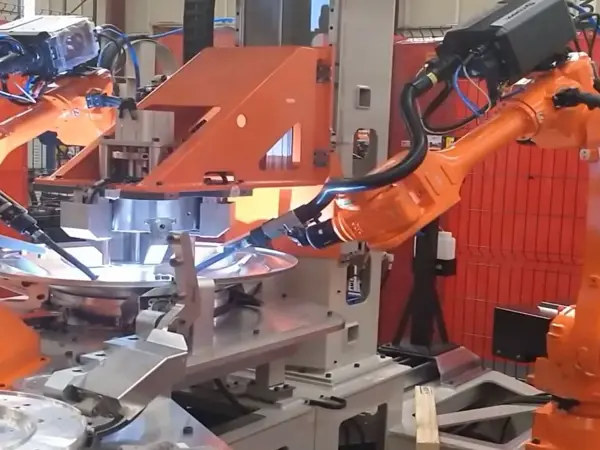

Watch Now: Synchronised MIG welding robots partially assemble a commercial washing machine drum.

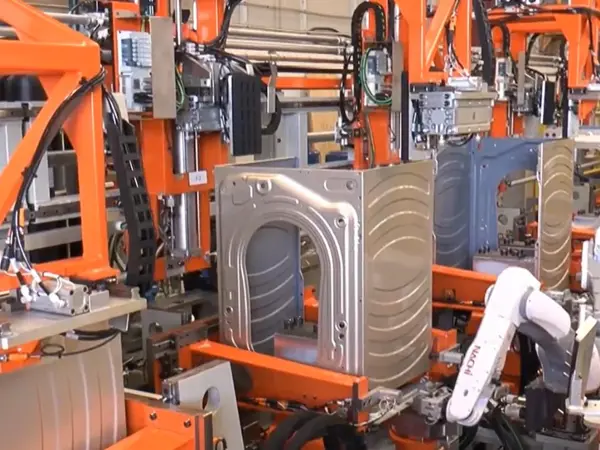

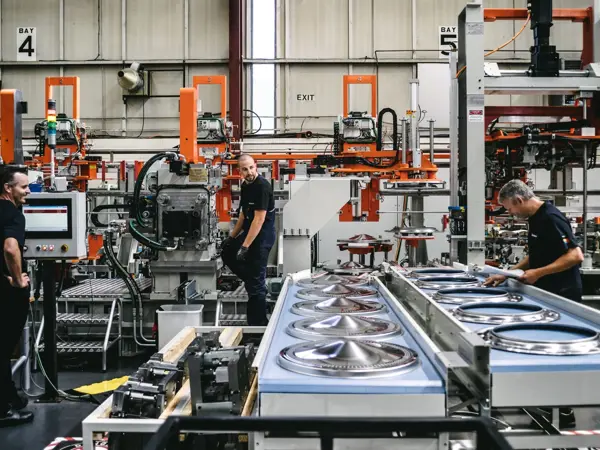

Watch: Utilising a range of technologies and managing a revised approach of building select projects closer to market, this project for a major home appliance manufacturer is a story of co-creation.

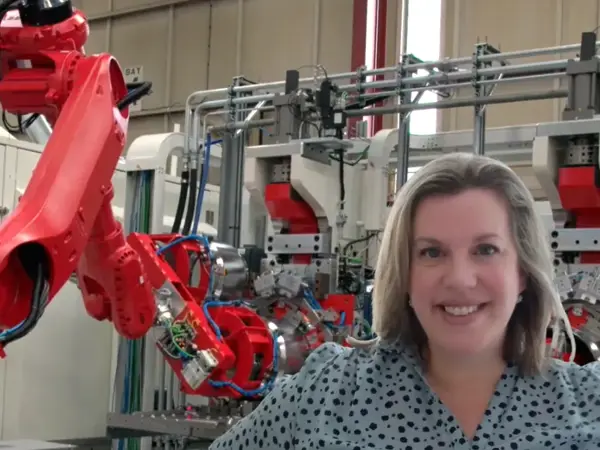

With a career that has taken her across the globe, Yan completed her PhD in the USA prior to working on offshore oil rigs in Norway. Today, she's on dry land unlocking manufacturing excellence with Facteon.

Jonathan reflects on his journey from Engineering Grad to Design Engineer with Facteon.

Watch Now. Robotics. Machine vision. Custom machinery.

Here's how to action powerful business change in your facility.

As the COVID-19 pandemic invalidates many predictions of where the manufacturing industry (and the world) would be today, we work to adjust to this new reality.

Facteon's Industrial Insights video series explores emerging technologies and their roles in your factory.

Facteon's Industrial Insights video series explores emerging technologies and their roles in your factory.

Unleash your facility's potential with Facteon's Industrial Insights video series. It's made for manufacturers like you.

Focused on simplifying cobot solutions, Robotiq is bringing robotics to manufacturers of all sizes.

Facteon's HR Coordinator shares the top lessons learned from working from home during the Coronavirus pandemic.

In under two hours, your machinery operators can become robot programmers with Universal Robots Academy.

Not only does Greg have one of the longest job titles at Facteon, he’s an integral part of delivering powerful IIoT solutions.

Facteon Group GM and Chief Optimist, John Cochrane, shares his vision for a stronger manufacturing industry following the COVID-19 pandemic with NZ Manufacturer.

Facteon announces two recently signed partnership agreements with major China-based robotics makers.

Facteon's Head of Finance, Tony Horton, talks onboarding in the age of isolation with CFO Magazine's staff editors.

Unleash your facility's potential with Facteon's Industrial Insights video series.

Global factory solutions specialist, Facteon, has bolstered its executive team with the appointment of a new Head of Finance.

Meet Toby, Facteon’s Project Engineer. He’s results-driven and determined to deliver for our customers.

You've overcome Roadblock 1: Where to start. The next roadblock you're likely to face is cost. Here's how to overcome it.

This article explores how to overcome this roadblock and shares a customer success story to inspire you to get started today.

How to convince your boss it's time to start your Industry 4.0 journey.

Rocket Lab is on a mission to increase access to space to improve life on Earth as the world’s leading dedicated small satellite launch provider.

Industry 4.0 adoption is a journey. At Facteon, we believe every manufacturer sits on the Industry 4. 0 adoption spectrum.

In China, there’s an emerging desire to serve technology-driven fields.

Recently, the Facteon team attended the 34th International Maintenance Conference (IMC).

As Facteon’s new Group General Manager, I have big plans for both our New Zealand and China businesses in 2020.

Global factory solutions specialist, Facteon, has appointed John Cochrane as the business’s new General Manager of Facteon Group.

Industry 4.0 and IIoT product development. To innovate successfully, three elements must be in play.

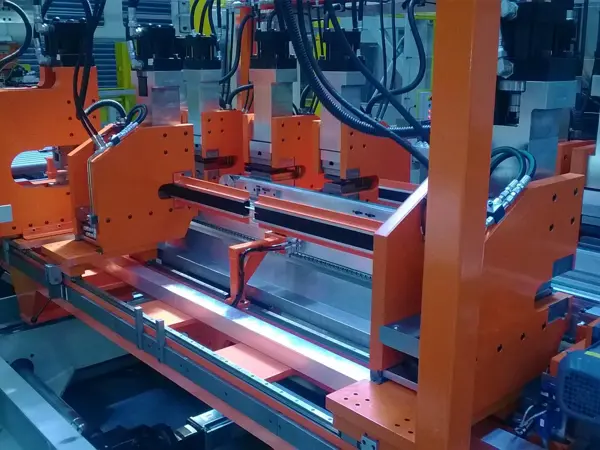

Facteon has worked closely with a global customer to design, manufacture, build and install a CNC rotary axis.

Our top five takeaways from China International Industry Fair 2019.

Facteon is pleased to announce our partnership with Universal Robots, the undisputed market leader in the cobot space.

Meet Steven. Armed with decades of factory maintenance experience, he has the skills your factory needs.

Facteon’s Head of Industrial IoT, Reinaldo Silva, attended Callaghan Innovation’s Southern SaaS 2019.

Facteon China’s rapidly growing team has recently moved into a new facility in Qingdao, Shandong, China.

Born from an international manufacturer that embraces Kaizen manufacturing principals, Facteon has inherited these principals. Over time, our business has evolved.

Many of Facteon’s Machine Shop projects are critical to our clients' successes. So, we’re sworn to secrecy via non-disclosure agreements.

Industry 4.0, Industrial IoT and digitisation are movements currently influencing the decisions of manufacturers across industries and countries.

One of New Zealand’s largest bottling companies is working with Facteon to implement a new manufacturing system to manage the maintenance of more than 700 machines across multiple plants.

Predictive maintenance offers clear advantages over both unplanned, reactive maintenance and traditional preventative maintenance.

Facteon looks ahead to predict the top smart manufacturing trends for the next 12 months.

The rise of smart manufacturing, Industrial IoT and Industry 4.0 has and will continue to revolutionise China’s manufacturing sector.

We have developed proprietary laser welding techniques and processes to ensure our customers are always competitive.

Manufacturing Manager, Phil Webb, catches up with Facteon’s most recent apprentice graduate, Patty Walsh.

The pace of robotic implementation across industries is accelerating.

Flexibility is key to survival. We need to constantly change our ways of thinking and manufacturing to thrive.

Bringing a new product to market, Aroa employed a world-class manufacturing expert.

The transition from university study to an internship can be a challenge. Now, Connor embarks on his next transition: Industrial IoT Intern to Junior Industrial IoT Engineer.

As manufacturing technology has evolved over the decades, IT has played an increasingly important role.

Here at Facteon, we're on the leading edge of automation, robotics and software systems. We’re also working to explore the potential of 3D vision systems.

Facteon’s machine building process has been honed over decades. We keep many of our key processes in-house to ensure Facteon standards are met.

The manufacturing industry’s continued commitment to Industry 4.0 and Industrial IoT has contributed to pressure on manufacturers to continuously upgrade and improve their operations.

Global specialists in intelligent manufacturing, Facteon (formerly Fisher & Paykel Machinery), has appointed John Cochrane as the company’s new Group Sales Manager.

2018 has been a big year for our business, exceeding our expectations with record project numbers.

When the world’s leading manufacturers need an automated production line, they turn to Facteon. The reason? We have extensive experience in appliance manufacturing and factory automation design.

Facteon takes pride in offering innovative and high accuracy machining capabilities. We have a dedicated, in-house Machine Shop.

An increasing number of manufacturers are under pressure to produce outstanding products and reduce their costs in a competitive market.

As the manufacturing industry continues to develop, the widespread use of Industrial Internet of Things (Industrial IoT) technologies and Industry 4. 0 principles shows no signs of slowing.

As an Advanced Quality Engineer at GE Appliances, Kazie Jasnowski is an expert in the field of laser welding. Kazie is visiting Facteon Headquarters in Auckland, New Zealand to share his knowledge with our team.

Industry 4.0 offers great benefits, and many potential pitfalls, for manufacturers as they try to stay competitive in a world in which digital transformation is shaping the manufacturing industry in profound ways.

The manufacturing sector is fast catching on to the idea that the Industrial Internet of Things (Industrial IoT) and Industry 4.0 are the way forward.

Wayne is responsible for investigating and developing both emerging and established machine automation technologies.

For the past 8 years, Reinaldo has been helping businesses to build and commercialise complex software products for a variety of industries.

As manufacturers move from legacy installations towards Industry 4.0 systems driven by the Industrial Internet of Things (Industrial IoT), they’re faced with the problem of decoding what, exactly, they’re buying into. There’s a raft of confusion regarding the terminology.

With more than three decades of experience in design and engineering, Trent is ready to take on his next challenge as Facteon’s Design Manager.

- « Previous

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- Next »