When we emerge from this pandemic (whenever that may be), we can shape a more robust manufacturing industry that is able to respond to consumer demand rapidly and produce products more efficiently than before.

A report found that one in four US manufacturers are considering automation as a result of the COVID-19 pandemic. I would suggest that the quarter of US manufacturers who act now will emerge in a position of strength and more agile than before.

However, it spans beyond automation. There are three key forces shaping manufacturing in a post-COVID world. From data to a culture of operational agility, here is your guide to a future-proof factory.

Data & Traceability

The role of data in the future factory cannot be overstated. It allows manufacturers to make decisions based on machinery information in real time, as opposed to assumed patterns or incomplete data. With food fraud predicted to rise due to the pandemic, it’s time for manufacturers to take proactive steps to track their supply chains. “One step back and one step forward” tracing simply does not suffice. That’s where data comes in. Manufacturers can understand what product has come into contact with which machine. Such technologies also trace the progression of a product from raw materials through to finished goods. You can learn more about traceability from my colleague, Reinaldo, here.

The power of data spans far beyond traceability. With manufacturers under mounting pressure to minimise the number of people in their facilities due to social distancing requirements, the need for people to be on-site to monitor machinery performance and to respond in the event of a breakdown is problematic.

For this reason, we expect an increase in demand for Cloud-based manufacturing monitoring systems that allow maintenance teams to track factory performance remotely. Systems offering predictive, rather than reactive, maintenance are a critical tool in minimising the risk of unexpected breakdowns. With manufacturers facing increasing pressure to minimise the number of staff on-site, it is essential that maintenance is streamlined and scheduled accurately.

Robotics

The intersection of the COVID-19 pandemic and the Industry 4.0 movement has created a unique storm in which robotics have become both essential and affordable for manufacturers of all sizes. Consider the need for several food processing plants to shut down to complete deep cleaning following employees contracting COVID-19. Such scenarios highlight the risk of human labour. With labour shortages and social distancing requirements in play, many manufacturers are facing increasing pressure to implement automation.

Many manufacturers are coming to the realisation that COVID-19 is likely to be with us for the foreseeable future. Therefore, the short-sighted approach of forging ahead with pre-COVID processes and ways of operating is flawed. The reality for manufacturers (and the world) is that our existence will likely be permanently altered. Manufacturers, much like other businesses, are now presented with a choice: Act now and thrive or continue and hope to survive.

In a post-COVID world, robotics is a pillar of the future factory. The ability to pivot rapidly to continue operating despite shifting demands. The competitive advantage of guaranteeing the ability of your operation to continue operating despite any government mandated COVID response is immense. For manufacturers looking to get ahead of the competition, now is the time to consider robotics.

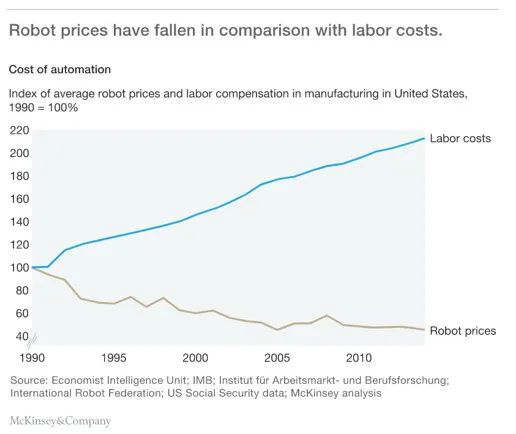

A robotics implementation is often blacklisted as too expensive or risky. The stats speak for themselves. Robotics is becoming cheaper.

Manufacturers are often quick to stop a robotics implementation in its tracks because it is deemed too risky. What is often ignored is the risk of doing nothing. Potential efficiency gains, flexibility, quality improvements and more are all lost if business as usual continues.

If this has spurred your business into action, start small with a pilot project. For more on this, here is our guide to getting started, along with an inspiring customer success story.

Flexible Operations

While robotics allows for operational flexibility on the factory floor, flexibility starts at the top of every organisation. The stories of manufacturers pivoting from producing hockey and lacrosse masks to medical shields and ethanol to hand sanitiser show the need to pivot to meet your market. While your business’ pivot may not have been as extreme, the pandemic has highlighted the need for operational flexibility on an unprecedented scale.

As data, traceability and robotics are pillars of the future factory, flexible operations are the foundation. Consider your organisation’s culture and its response to change. The pandemic has changed our world. Manufacturers now have a choice: adapt and thrive or fight to survive. Which will your factory choose?